Breaking Free from MRP: Simplifying Manufacturing Workflows

Material Requirements Planning (MRP) is a crucial aspect of supply chain management, as it helps organizations to efficiently manage the flow of materials and ensure that the right amount of raw materials, components, and finished products are available when required. However, MRP comes with its own set of challenges, which include significant configuration needs and administrative overhead. These challenges can be addressed by implementing a smart min/max planning setup and accompanied by a full featured work order management system.

One of the major challenges of MRP is its significant configuration needs. MRP requires a considerable amount of setup and configuration, which can be time-consuming and complex. For example, an organization must first set up its bill of materials, routing, and inventory parameters to ensure that the MRP system accurately calculates and forecasts the demand for materials. Furthermore, MRP systems often require a significant amount of manual data entry and maintenance, which can be prone to errors and omissions.

Perhaps one of the most challenging aspects of MRP is the administrative overhead associated with its implementation. MRP systems can be difficult to manage and maintain, which can result in increased costs and decreased productivity. For example, organizations must allocate resources to manage the MRP system, which can take away from other areas of the business. Additionally, MRP systems are often complex and difficult to use, which can lead to frustration and a lack of user adoption.

To overcome these challenges, organizations can look to implement a smart min/max planning setup that will work in conjunction with setting up work orders as part of the production flow. This approach utilizes data science-infused forecasting techniques to accurately predict demand, which helps organizations to leverage economic order quantity (EOQ) to right-size inventory levels, minimizing stockouts and identifying the perfect level of efficiencies where holding costs are maintained at desirable levels. By accurately predicting demand, organizations can avoid overstocking and minimize the risk of stockouts, which can lead to lost sales and decreased customer satisfaction.

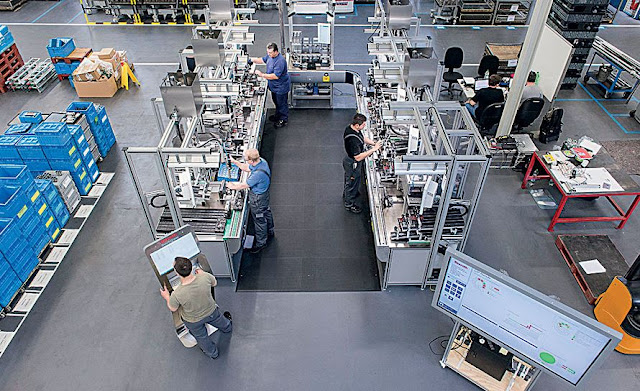

In addition to smart min/max planning, a work order system can help organizations to streamline their manufacturing workflows. A mature Computerized Maintenance Management System (CMMS) can provide a range of features that utilize parent-child work order relationships to facilitate the manufacturing process. For example, organizations can use the CMMS to create and track work orders, manage inventory, and automate the scheduling and tracking of maintenance tasks. By utilizing these features, organizations can streamline their manufacturing process and minimize downtime, which can lead to increased productivity and decreased costs.

Streamlining Manufacturing: The Power of Parent-Child Work Orders

A parent-child work order system allows organizations to manage their manufacturing workflows more efficiently by allowing related tasks to be associated with a parent work order. The parent work order acts as a master task, and the child work orders represent the underlying tasks that need to be completed. This system allows organizations to manage the workflow of multiple tasks in parallel, resulting in increased productivity and decreased costs.

In a parent-child work order system, the parent work order is typically created first, and it includes information about the overall task that needs to be completed. The child work orders are then created and associated with the parent work order, and they contain information about the specific tasks that need to be completed. This system allows organizations to manage and track the progress of multiple tasks at once, as all the child work orders are linked to the parent work order.

One of the key benefits of a parent-child work order system is that it allows organizations to work in parallel, as each child work order can be assigned to a different team member or department. This means that multiple tasks can be completed simultaneously, reducing the overall time it takes to complete the project. Additionally, the parent-child work order system allows organizations to manage interdependent tasks, as the completion of one task can trigger the start of another task.

Furthermore, a parent-child work order system provides organizations with a clear and concise view of the progress of their manufacturing workflows. All the related tasks are associated with the parent work order, making it easy for organizations to see the status of each task and the overall progress of the project. This information can then be used to make informed decisions about the workflow, such as adjusting the schedule or reassigning tasks to different team members.

Essentially a parent-child work order system provides organizations with a flexible and efficient way to manage their manufacturing workflows. By allowing related tasks to be associated with a parent work order, organizations can work in parallel and manage interdependent tasks, leading to increased productivity and decreased costs. Additionally, a parent-child work order system provides organizations with a clear and concise view of the progress of their workflows, enabling them to make informed decisions about the workflow.

Controlling The Chaos: The Benefits of End-to-Start Dependency Work Orders

An end-to-start dependency work order system is a type of work order system that is used to orchestrate a manufacturing workflow by establishing a relationship between two tasks. This relationship specifies that one task must be completed before another task can start. This type of work order system is often used in manufacturing processes where there is a clear sequence of tasks that need to be completed in a specific order.

In an end-to-start dependency work order system, the first task is considered the end task, and the second task is considered the start task. Once the end task is completed, the start task can begin. This type of work order system provides organizations with a clear and concise view of the dependencies between tasks, allowing them to manage their manufacturing workflows more efficiently.

One of the key benefits of an end-to-start dependency work order system is that it allows organizations to control the flow of work, ensuring that tasks are completed in the correct order. This reduces the risk of errors and rework, leading to increased productivity and decreased costs. Additionally, end-to-start dependency work orders provide organizations with a clear understanding of the interdependencies between tasks, enabling them to adjust the workflow as needed.

The advantages of an end-to-start dependency work order system is that it provides organizations with real-time information about the status of their manufacturing workflows. The system can automatically update the status of a task as it is completed, allowing organizations to see the progress of the workflow in real-time. This information can then be used to make informed decisions about the workflow, such as adjusting the schedule or reassigning tasks to different team members, and most importantly get analytics and metrics that can be used to fine tune cycle times and thus increasing throughput.

As you can see, an end-to-start dependency work order system provides organizations with a flexible and efficient way to manage their manufacturing workflows. By establishing a clear relationship between tasks, organizations can control the flow of work, reducing the risk of errors and rework. Additionally, end-to-start dependency work orders provide organizations with real-time information about the status of their workflows, enabling them to make informed decisions about the workflow.

No Task Left Behind: The Advantages of Follow-Up Work Orders in Manufacturing

A follow-up work order is an important tool used in setting up a manufacturing workflow. This type of work order is used to ensure that tasks are completed as intended, and to identify any issues or problems that may arise during the manufacturing process. The follow-up work order is typically used in conjunction with other types of work orders, such as parent-child work orders and end-to-start dependency work orders.

The follow-up work order is used in several different stages of the manufacturing process, including inspection, quality assurance, and stress testing. During inspection, the follow-up work order is used to ensure that all tasks have been completed as required, and to identify any issues or problems that may have arisen. Quality assurance processes are also an important part of the manufacturing workflow, and the follow-up work order is used to ensure that products meet the required standards.

Stress testing is another important use of the follow-up work order in the manufacturing process. This process is used to identify any weaknesses or limitations in the manufacturing process, and to determine how products will perform under different conditions. The follow-up work order is used to track the progress of stress testing and to identify any areas that may need improvement.

One of the key benefits of using a follow-up work order in the manufacturing process is that it provides organizations with a clear and concise view of the progress of the workflow. The follow-up work order can be used to track the completion of tasks, and to identify any issues or problems that may arise. This information can then be used to make informed decisions about the workflow, such as adjusting the schedule or reassigning tasks to different team members.

Another advantage of the follow-up work order is that it allows organizations to control the flow of work, ensuring that tasks are completed in the correct order. This reduces the risk of errors and rework, leading to increased productivity and decreased costs. Additionally, the follow-up work order provides organizations with a clear understanding of the interdependencies between tasks, enabling them to adjust the workflow as needed.

The follow-up work order is a critical tool in setting up a manufacturing workflow. This type of work order is used in several stages of the manufacturing process, including inspection, quality assurance, and stress testing. The follow-up work order provides organizations with real-time information about the status of their manufacturing workflows, enabling them to make informed decisions about the workflow. By using the follow-up work order, organizations can control the flow of work, reducing the risk of errors and rework, and increasing productivity and efficiency.

A Winning Combination: Min/Max Planning and Work Order Management

Implementing smart min/max planning and combining it with a full-featured work order management system can be a game-changer for organizations. This approach can help remove the pitfalls and significant overhead of running full-blown MRP, as well as provide a more streamlined and efficient approach to managing inventory and production processes. The benefits of this approach include reduced inventory costs, improved accuracy in inventory management, and greater visibility into production processes, among others. With the right tools and processes in place, organizations can effectively manage their resources and meet the demands of their customers.

Comments

Post a Comment